NEWS CENTER

25

2025

-

12

Why Do Automotive Silicone Hoses Crack?

Author:

Why Do Automotive Silicone Hoses Crack?

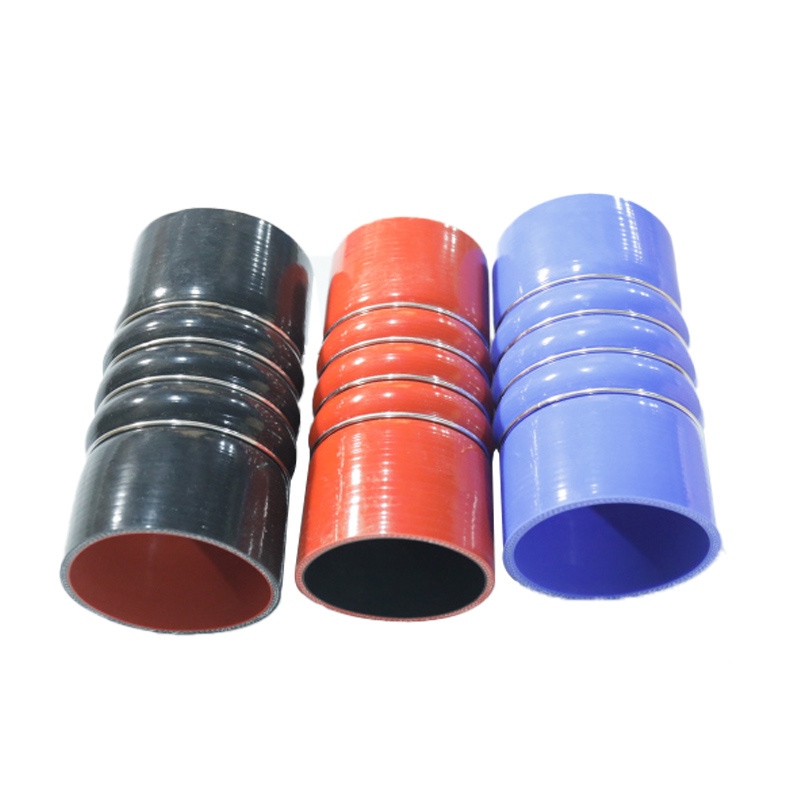

Automotive silicone hoses are widely used in cooling systems, heater hoses and engine thermal management applications due to their flexibility and high-temperature resistance.

However, many users encounter a common problem after a period of use: silicone hose cracking.

So why do automotive silicone hoses crack, and how can this issue be avoided? The answer lies in material quality, reinforcement structure and manufacturing process.

Common Causes of Automotive Silicone Hose Cracking

1. Low-Grade Silicone Material with Poor Heat Resistance

The engine compartment is a high-temperature environment with constant thermal cycling.

When low-grade or general-purpose industrial silicone is used, the material gradually ages, leading to:

Surface hardening

Micro-cracks

Eventual structural cracking

This type of failure usually appears after several months of operation rather than at the initial stage.

2. Insufficient Reinforcement Structure

High-quality automotive silicone hoses are engineered components, not simple rubber tubes.

Hoses with:

Low-density reinforcement

Too few fabric layers

Inconsistent reinforcement bonding

are more likely to crack under pressure pulses, vibration and bending stress, especially at curved sections and connection points.

3. Improper Manufacturing Process

Simple extrusion processes often result in:

Uneven wall thickness

Non-uniform stress distribution

Over time, stress concentration areas become the starting point for cracks, particularly near hose ends and bends.

4. Hose Design Not Matching Actual Working Conditions

Cooling hoses, heater hoses and high-temperature lines operate under very different conditions.

Using a hose beyond its designed temperature or pressure range significantly increases the risk of cracking, even if the material is silicone.

What Makes a High-Quality Automotive Silicone Hose?

1. Stable Automotive-Grade Silicone Compound

Automotive-grade silicone compounds are designed for:

Long-term heat resistance

Excellent aging performance

Flexibility under repeated thermal cycling

This ensures the hose remains stable throughout its service life.

2. Multi-Layer Polyester Fabric Reinforcement

Reinforced silicone hoses typically feature multiple layers of polyester fabric, which provide:

Higher pressure resistance

Improved fatigue strength

Better dimensional stability

This structure is especially critical for curved hoses and high-stress areas.

3. Hand-Wrapped Reinforcement Construction

Compared to basic extrusion, hand-wrapped reinforcement construction allows precise control of fabric orientation and tension.

This results in:

More uniform stress distribution

Reduced risk of delamination

Longer service life in demanding applications

Why More Customers Choose DIAO Automotive Silicone Hoses?

DIAO focuses on long-term performance and reliability, not short-term cost reduction.

Automotive-Focused Design Philosophy

DIAO silicone hoses are engineered specifically for industrial-grade automotive cooling and heater applications, ensuring proper matching of:

Temperature range

Pressure requirements

Hose geometry

Hand-Wrapped Multi-Layer Reinforced Structure

DIAO hoses utilize hand-wrapped multi-layer polyester reinforcement, delivering consistent strength, flexibility and durability under continuous engine operation.

Long-Term Reliability over Initial Cost

By prioritizing material stability and structural integrity, DIAO helps customers:

Reduce hose replacement frequency

Minimize downtime and maintenance risks

Improve overall system reliability

Conclusion: Cracking Is a Quality Issue, Not a Silicone Issue

Silicone hose cracking is not caused by silicone itself, but by material selection, reinforcement design and manufacturing quality.

Choosing a well-engineered automotive silicone hose is essential for long-term, trouble-free performance.

For applications where durability and reliability matter, high-quality automotive silicone hoses make a measurable difference.

automotive hose connectors,silicone hoses for cars,bend rubber hose,silicone air intake hose,3 inch rubber hose,car engine hoses,10 inch flexible hose,wire reinforced hose,cooling hose manufacturer

Previous page

Next page

Previous page

Next page